- 18 September 2025

Cold Chain Logistics: Monitoring and Treatment

Cold treatment of fresh produce involves using refrigeration to lower the temperature of fruits and vegetables to a specific level for a set period to eliminate pests, particularly those that burrow inside the produce. This is crucial for meeting import requirements of countries with strict phytosanitary regulations, such as Australia, the US, China and India to name a few.

Cold Treatment is used in many instances but mainly for export produce. This can be done either In-Transit or Onshore.

In-Transit vs Onshore

In-transit

Refers to products loaded into a seafreight container equipped with temperature probes. These probes are checked on arrival to confirm the temperature stayed below the allowed maximum, ensuring the product remained properly treated during the ocean journey.

The in-transit process begins with the shipping line preparing the container. The testing of the temperature probes and the cold treatment is carried out under the supervision of an approved officer, which Mainfreight can assist with.

Benefits

The benefit is that there are no delays, as the treatment is completed during transit. The treatment period is the same whether it occurs in transit or onshore.

Disadvantages

Issues can arise if any probes fail or the temperature rises above the maximum during the voyage. In that case, the treatment must restart for the full onshore duration once the container reaches its destination. While the conditions can now be monitored during transit, no corrective action can be taken until the container arrives at port.

On-shore

This method is used for both airfreight and seafreight shipments, with treatment times ranging from 3 to 23 days depending on the product and the destination country’s requirements.

Some countries are considered protocol markets, meaning they have formal government-to-government agreements that set specific import conditions, such as approved treatments, temperature requirements and inspection procedures.

These markets may allow fumigation followed by cold treatment, but both treatments must be completed at the same facility and this shortens the overall process. An example would be plums exported to China from Australia.

Two types of On-shore treatments

-

Combination treatment – Fumigation (3 hours) and Cold Treatment (4 days).

-

Only Cold Treatment – Ranges from 16 – 21 days

How Cold Treatment is set up?

Both onshore and in-transit treatments follow the same process: the product is cooled to the required temperature and then placed in a Cold Treatment room.

-

Once in the Cold-Treatment room, the probes are calibrated twice to ensure readings are correct.

-

Probes are placed through the centre of the product ensuring the probes are completely covered.

-

The doors are sealed and treatment begins.

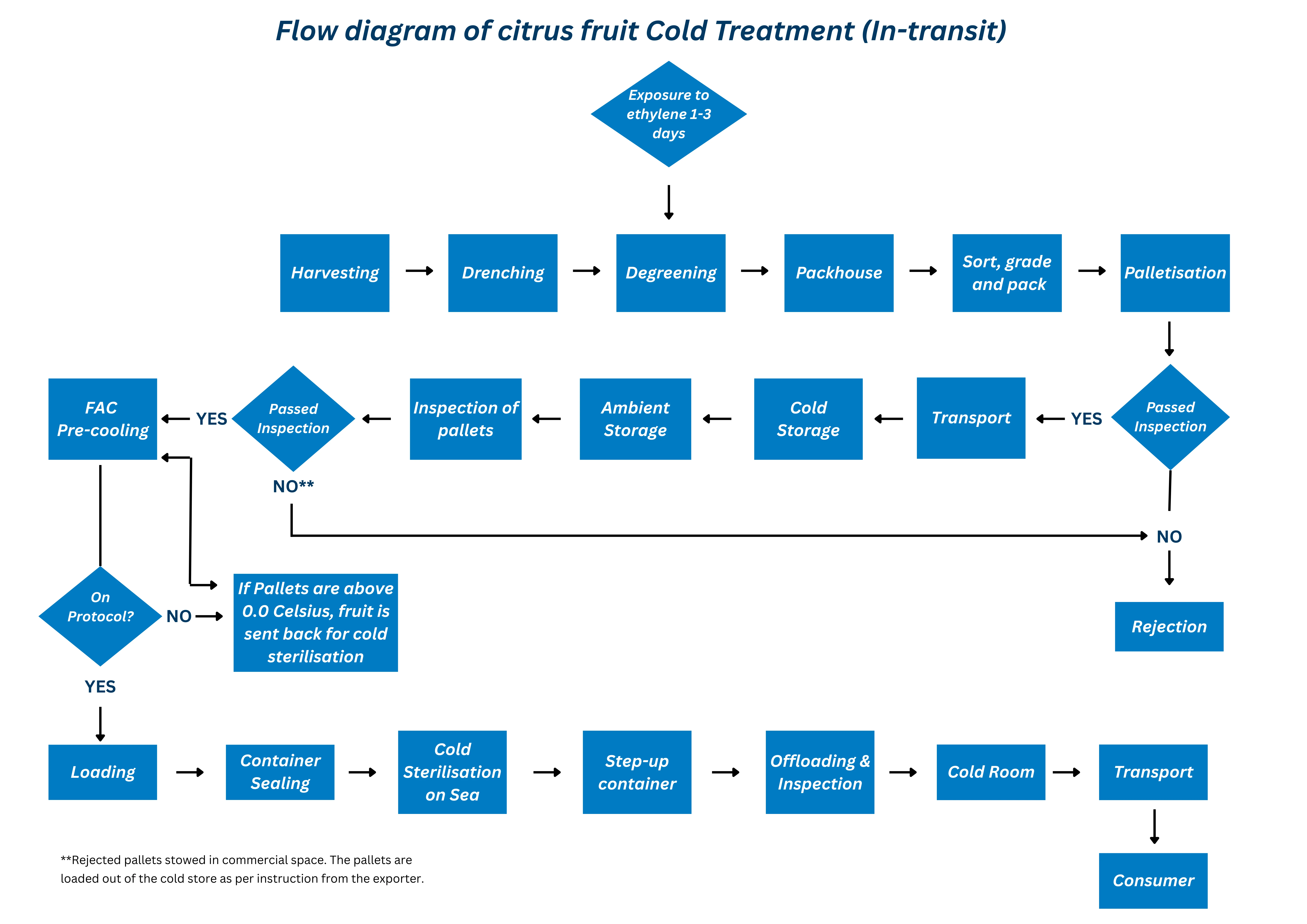

Below is a flow chart for the Cold Treatment of citrus. It should be noted that a “fail” at any stage restarts the Cold Treatment process.

Mainfreight can guide you through the entire cold-chain process, with the expertise and facilities to monitor your freight closely and address any issues immediately. Our facilities include designated Cold Treatment rooms and our team have the knowledge to meet all quarantine requirements.

Air & Ocean Services

Our growing worldwide network offers over 28,000 Mainfreight to Mainfreight connections. Find out more about our air freight and sea freight services.

Find out more here